Occupational Exposure- Healthy Lung Month (October)

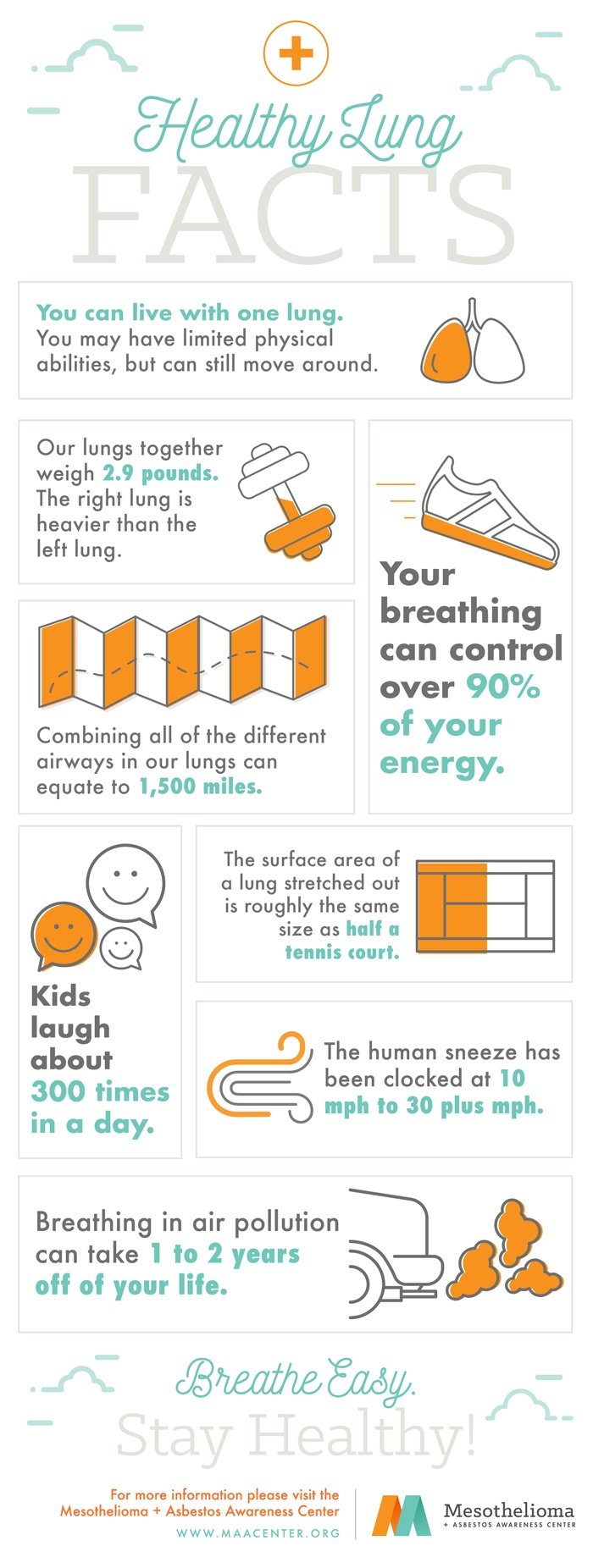

We all know how important it is to maintain a clean, healthy, and compliant work environment, so in support of National Healthy Lung Month (HLM), we are going to focus on workplace air quality. Occupational exposure to common and potentially hazardous airborne debris or bacterial contaminants can have a big impact on an employee’s immediate and long term health. Varying based on the occupation, prolonged exposure to toxic air can be hazardous to laborers in both high and low concentrations. Common industrial gases and toxic dusts can cause damage to the lungs, resulting in serious conditions, cancers, and even death. So to help those most at risk, we are sharing common air pollutants based on specific occupations.

How safe is your occupation?

Airborne pollution, dusts, and hazardous contaminants are everywhere, however, there are a number of things employers and employees can do to prevent on the job exposure. The first step is to be aware of potentially high risk occupations and the specific workplace hazards.

Construction

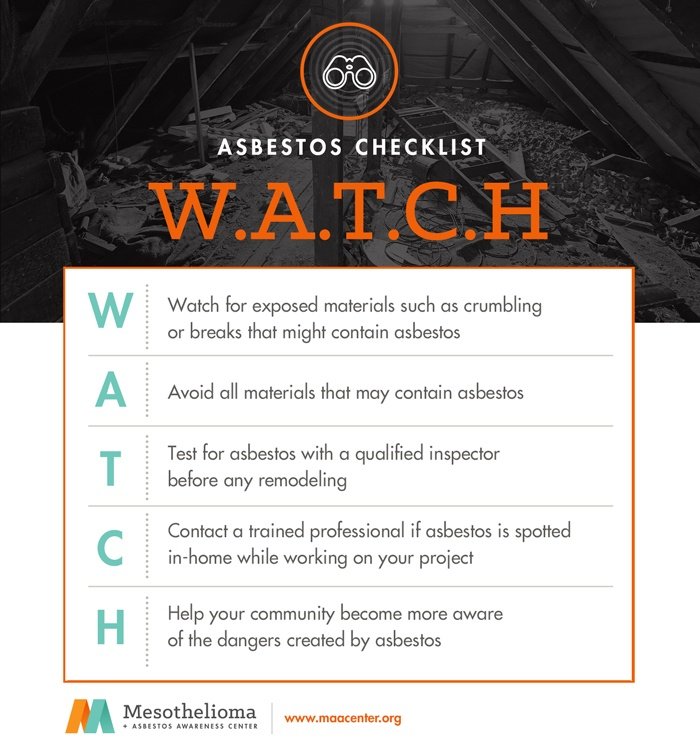

Dusts and gases that are generated during the fabrication, installation, and removal of common construction materials poses a serious threat to respiratory health. If allowed to become airborne, contaminants can be carried by the wind or linger in the air. Consistent exposure can cause occupational asthma or COPD whereas severe damage includes lung diseases and cancers. Contractors, masons, insulators, and plumbers can come in contact with volatile organic compounds and common solid contaminants including silica, asbestos, and lead. Silicosis, caused by silica attacks the lungs, resulting in the formation of scar tissue that reduces lung function, eventually causing death. Asbestos causes mesothelioma, a rare long-term survival disease that attacks the lungs and causes the formation of scar tissue.

Chemical Manufacturing

The production, use, and storage of harsh chemicals can release harmful fumes during everyday operation, while leaking equipment and spills also contribute to hazardous conditions. Common to industrial cleaning and operation, man-made chlorinated solvents like trichloroethylene (TCE) are carcinogenic liquids used in commercial manufacturing and degreasing applications. Both short and long-term exposure and inhalation of TCE affects the nervous system causing dizziness, respiratory issues, organ damage, and cancer. It’s essential for employees to report any leaks or spills immediately, as well as follow proper safety precautions when handling, using, and storing chemicals.

Mining, Tunneling, and Industrial Manufacturing

Miners, tunnel workers, and industrial fabricators can come in contact with a variety of toxic debris and gases. Welding gases, coal dust, silica, and beryllium are commonly found contaminating the air in industrial applications. Miners exposed to high-carbon coal dust can development coal pneumoconiosis, resulting in decreased pulmonary function due to the inflammation of the lungs bronchioles. Occupational welder’s often come in contact with both metal and gaseous fumes released as a byproduct of the process. Metal fumes like beryllium and lead and the the other gases released become toxic with prolonged exposure, causing cancers to develop in the throat and lungs. It’s important for employees to use their safety equipment at all times.

Medical Industry

Working in the medical industry you are surrounded by risks daily. The risks are so small, you can barely see them most of the time. Bloodborne pathogens are cause for concern whether you are a doctor, nurse, or janitor. The three most common diseases transmitted that are addressed in the Bloodborne Pathogen Standard are Hepatitis B (HBV), Hepatitis C (HCV), and the Human Immunodeficiency Virus (HIV).

Health care workers are potentially exposed to these diseases in one of two ways:

- A percutaneous injury in which a health care worker is injured by a sharps object, or

- Contact of mucous membrane or non-intact skin with blood, tissue, or other potentially infectious bodily fluids.

In order for medical personnel to remain protected if a body-fluid spill occurs, we recommend having a Universal Precaution Compliance Kit on hand.

Prioritizing Risk Prevention

Every individual should prioritize workplace safety. Wearing the proper protective equipment, reporting spills, and even re-stocking the first aid kit are simple actions that can potentially save a life. It is the employer’s responsibility to comply with and enforce OSHA guidelines while on the job. However, following safety protocol and limiting contact with hazardous solids, liquids, and gases ultimately comes down to the individual. Therefore, it’s the responsibility of every employee to address any compliance, equipment, or safety issues immediately.